- Sustainability

- Social

- Safety & Health

Safety & Health

- Sustainability

- Social

- Safety & Health

Safety & Health

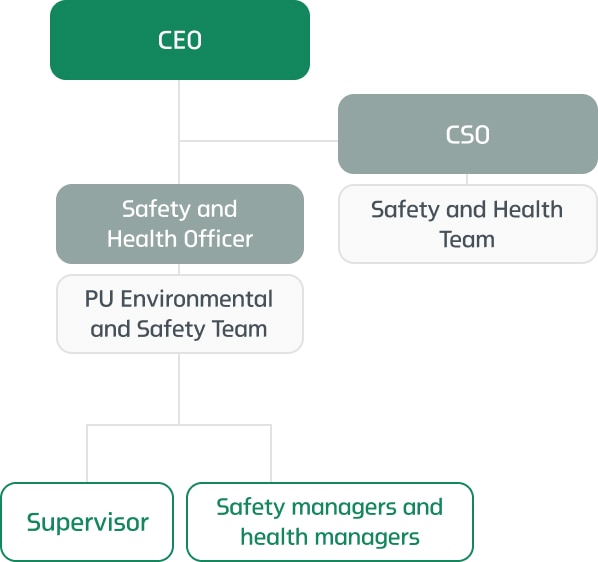

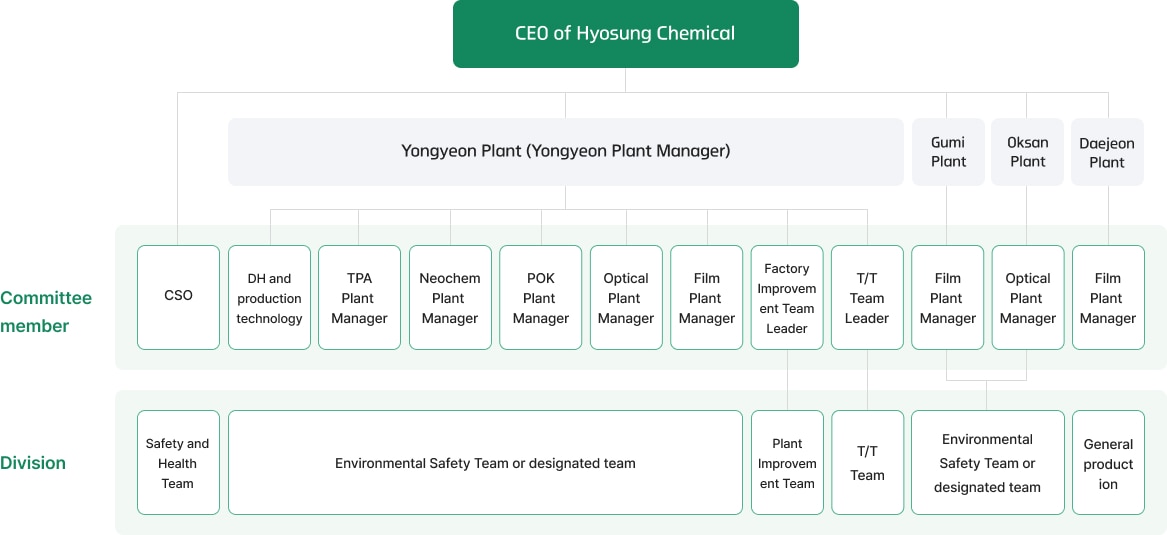

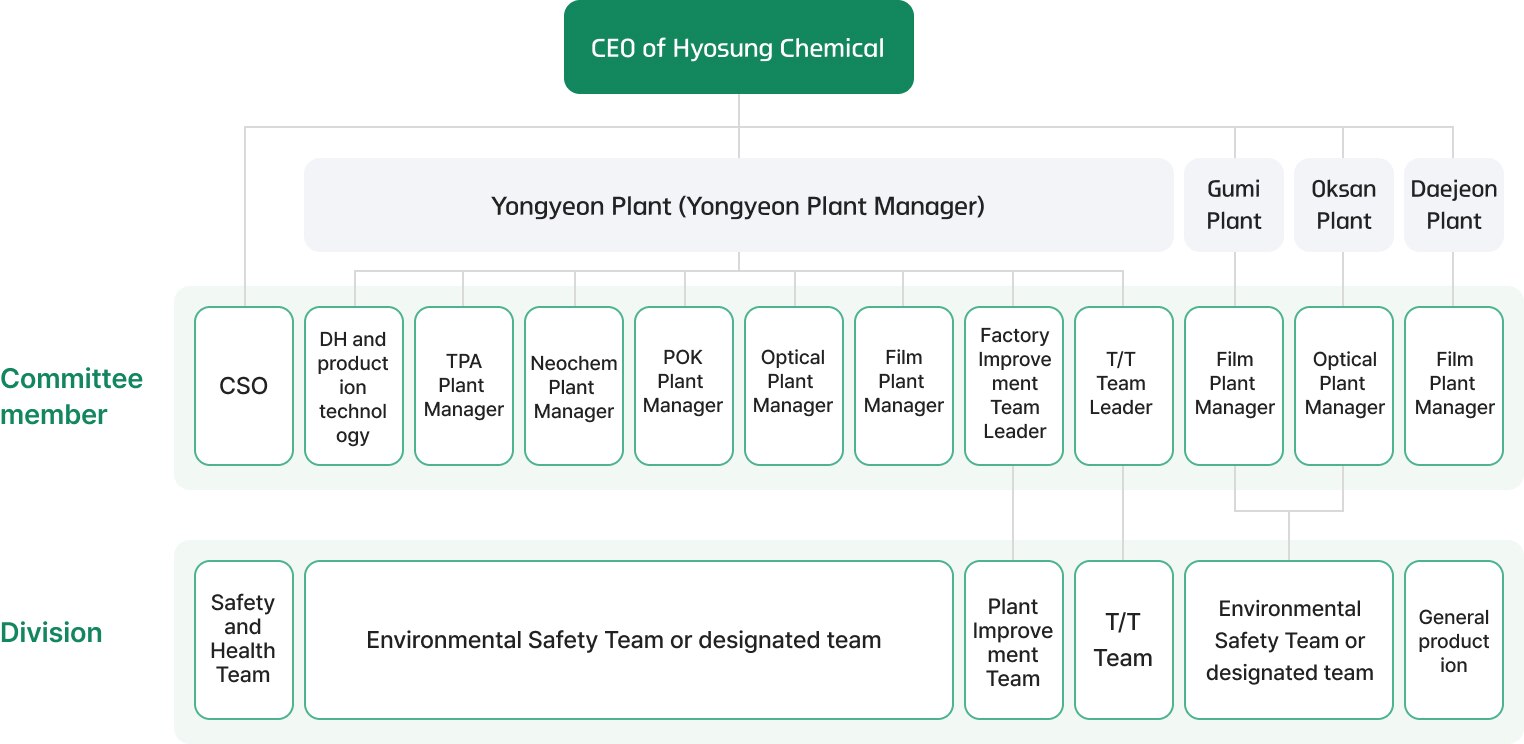

Safety & Health Organization

With the aim of reinforcing safety & health in accordance with the enactment of the Serious Accident Punishment Act, Hyosung Chemical appointed a Chief Safety Officer (CSO) under the direct supervision of the CEO and established a department dedicated to safety and health.

In addition, the EHS Committee meets every month to evaluate and resolve issues pertaining to the company's environment, health, and safety, as well as to manage risks by managing and supervising business execution and the current status.

Company-wide safety and health organization

* CSO(Chief Safety Officer)

EHS Committee

|

* EHS(Environment Health Safety)

SHE Management Policy

Guided by responsible management and an execution-focused organizational culture, Hyosung Chemical practices Safety, Health, and Environment (SHE) as the highest priority across

all management activities.

We are committed to establishing a zero-accident, incident-free workplace and growing into a trusted company together with our employees, partners, and stakeholders.

-

1. Strengthening SHE Execution Capabilities based on Responsible Management

- Hyosung Chemical employees manage SHE Goals in a Performance-Oriented manner

and establish a system that ensures effective execution at worksites. -

2. Accident Prevention through Proactive Risk Management and Regulatory Compliance

- We proactively manage Potential risk Factors through risk assessments across all processes, facilities, and operations.

In addition, we prevent industrial accidents, chemical incidents, and environmental accidents by strictly complying with domestic and international SHE regulations. -

3. Securing SHE Competitiveness Through AI and Data

- We predict risks through the use of AI and data-driven decision-making,

and continuously enhance the efficiency and accuracy of SHE management. -

4. Establishing a Safety Culture Based on Communication and Teamwork

- We foster an autonomous and sustainable safety culture through education and communication,

with active participation from both employees and partners. -

5. Environmental Protection and Prepartion for a Sustainable Future

- We practice ESG management and pursue a sustainable future through the efficient use of resources and energy,

as well as the development of eco-friendly processes and technologies.

January 1, 2026

Lee Cheon-seok,

CEO of Hyoung Chemical

HSE Management System

Hyosung Chemical established a health, safety, and environmental (HSE) management system in order to conduct systematic safety and health activities, and continuously assess and enhance the system's suitability, sufficiency, and efficacy using the PDCA cycle.

|

Action : Management review

|

EHS Management long-term roadmap

Hyosung Chemical selects safety and health as the top priority when making management decisions and has established an EHS Management long-term roadmap to put this into practice. Based on the roadmap, we will contribute to building a safe society by achieving zero accidents and zero accidents through continuous improvement and prevention activities.

|

*LTIFR(Lost Time injury Frequency rate) = Number of accidents requiring 3 or more days of absence from work (recovery)

* 1,000,000 / Total worker working hours (number of closed-day accidents per million working hours)

Safety and Health Promotion System

To achieve a workplace free of industrial accidents, we promote action-oriented safety activities by organizational unit and engage in self-driven safety activities by organizational unit.

- Raising awareness of safety activities

- Development of numerous safety-enhancing activities

- Management of goals and evaluation of organization’s safety activities

Promotion of proactive safety measures by organizational unit

Strengthening self-directed safety measures by organization

Implementing a workplace free of industrial accidents

Accomplishing accident-free sites

Safety and Health Promotion Activities

| Classification | Targets and tasks | Key performance indicators (KPIs) | Unit | 2023 plan |

|---|---|---|---|---|

| (1) Goal establishment and implementation | Establishment of HSE policies and goals | Establishment and management of policies | Established/ Not established |

Established |

| Achievement of zero-accident goal | Number of serious accidents | Cases | 0 | |

| Number of industrial accidents | Cases | 0 | ||

| (2) Verification and improvement of hazards / risk factors | Promotion and improvement of risk assessment | Number of cases identified/improved | Improvement rate(%) | 100 |

| Environmental Safety Patrol | Number of cases identified/improved | Improvement rate(%) | 100 | |

| Eradication activities | Number of cases identified/improved | Improvement rate(%) | 100 | |

| Near-misses identified and improved | Number of cases identified/improved | Improvement rate(%) | 100 | |

| (3) Listening to employee voices and improvement | EHS committee operation | Meetings conducted | Improvement rate(%) | 100 |

| PU environmental safety meeting | Meetings conducted | Improvement rate(%) | 100 | |

| Industrial Safety & Health Committee | Meetings conducted | Improvement rate(%) | 100 | |

| (4) Establishing and executing safety and health budget | Establishing and executing safety and health budget | Plan / Performance | Execution rate(%) | 100 |

| (5) Safety and health education and training | Employee safety and health education | Target / Provider | Improvement rate(%) | 100 |

| Emergency drill | Plan / Performance | Improvement rate(%) | 100 | |

| (6) Partner management | Partner council | Number of suggestions/improvement | Improvement rate(%) | 100 |

| Joint inspection of partners | Number of suggestions/improvement | Improvement rate(%) | 100 |

-

Safety inspection activities

-

EHS committee activities

-

Partner council activities

-

Partner council activities

-

CPR training activities

-

Fire drill